Why buy cialis on the internet is really beneficial for you?

So you’ve decided to order cialis and do not know where to start? We can give you some advice. First, ask your doctor for advice in order to properly determine the dosage, when you do that, you need to decide for yourself exactly where you will be buying the drug. You can buy cialis online, or you can just buy it at the pharmacy. Buy cialis online has a number of advantages, one of which is price. The cost of the Internet will always be lower than in stores, and when combined with the free shipping, it will be the best choice. Besides the price there are a number of advantages over conventional pharmacies, one of which is anonymity. Also, you can always check the online store on reliability, read reviews about it and the opinion of other buyers. Read more.

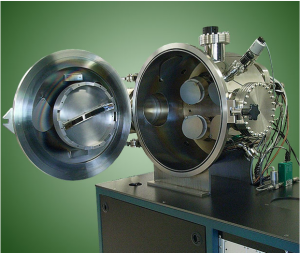

Thin film evaporation and deposition is essentially the application of an extremely thin film of material – relative to the size of a few atoms – onto what is known as a “substrate” surface. It is then coated with a specific material that is chosen by the operator to form layers. The process of thin film deposition is an integral part of today’s semiconductor industries, solar panel production, CD manufacturing, and other optical device industries.

Thin film evaporation and deposition is essentially the application of an extremely thin film of material – relative to the size of a few atoms – onto what is known as a “substrate” surface. It is then coated with a specific material that is chosen by the operator to form layers. The process of thin film deposition is an integral part of today’s semiconductor industries, solar panel production, CD manufacturing, and other optical device industries. One of the biggest challenges the global community faces in the coming decades is how to solve the fundamental problem of energy consumption. As expert

One of the biggest challenges the global community faces in the coming decades is how to solve the fundamental problem of energy consumption. As expert